Asu Machine Distribution

The Asu machine has indeed been creating quiet ripples over the last decade, applauded as an innovative indigenous device that has reduced the time taken to weave a Pochampally Ikat sari from about six hours to an hour and a half. It has revolutionised the productivity of handloom weavers in this district.

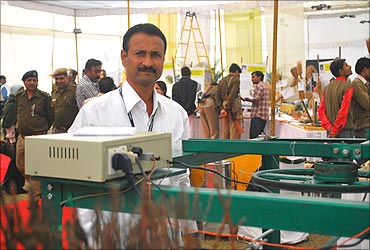

Before weaving various patterns on the loom, a hand winding process of yarn is required in the traditional ‘Tie & Dye’ Pochampalli silk saree tradition. This is a very tedious and cumbersome process and involves two and fro moving of the hand thousands of time in a span of four-five hours. Mallesham (37), a traditional weaver, has made a device to mechanize this process and relieve women, who generally do this task, from the drudgery involved.

Learning early: Chintakindi Mallesham was born in a traditional weaver’s family in a small village of handloom weavers, Sharjipet. His parents, Laxminaraan and Laxmi taught him to weaving from his tenth year onwards. By studying during nights and working during the day, he could complete his studies regularly till class seventh. Thereafter he took private tuitions to fulfill his desire of completing class tenth, which he could clear only after three attempts. But in view of weak financial condition of his family, he finally gave up studies in 1986. Though he did not have much time for other pursuits, he did like opening up dysfunctional radios and transistors and see the arrangement of components inside. Thank you!

Learning early: Chintakindi Mallesham was born in a traditional weaver’s family in a small village of handloom weavers, Sharjipet. His parents, Laxminaraan and Laxmi taught him to weaving from his tenth year onwards. By studying during nights and working during the day, he could complete his studies regularly till class seventh. Thereafter he took private tuitions to fulfill his desire of completing class tenth, which he could clear only after three attempts. But in view of weak financial condition of his family, he finally gave up studies in 1986. Though he did not have much time for other pursuits, he did like opening up dysfunctional radios and transistors and see the arrangement of components inside. Thank you!

Donate Now

Donate Now become a member

become a member sponsors

sponsors donors list

donors list